top of page

Robotics Testing

Showcasing my work on internal development projects at HEBI Robotics

160W Programmable Load

-

Four parallel BJT active sources

-

Active cooling with heat sink and 12V fan

- Programmable current source through dip switch connected to binary weighted resistor divider or direct reference voltage input

- Includes thermal shut-down with 10 degrees hysteresis

- Includes on-bard voltage and current measurement

- 48V power input, on-board buck regulators for 12V and 5V power rails

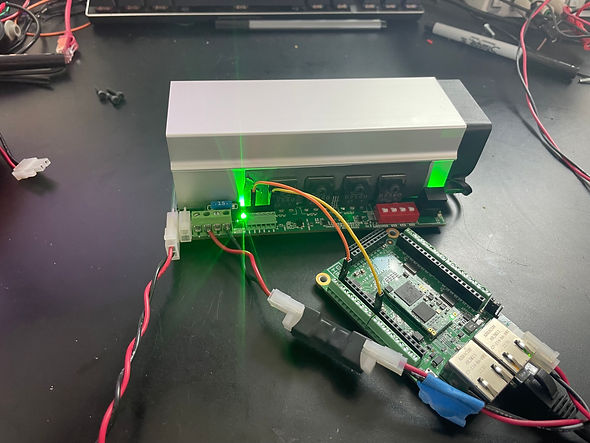

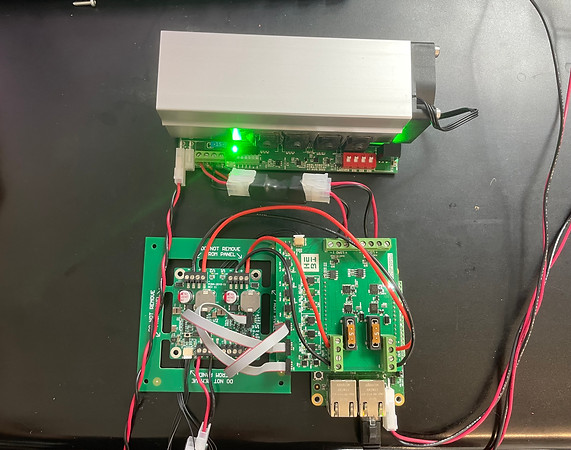

Dual DC Power Regulator Test Set-Up

-

My test board design connects to the I/Os of the power regulator board under test, as well as the programmable active load

-

I programmed the test board over ethernet with Python APIs to test the power regulators at 5, 9, 12 and 24V with a 4A load.

-

The test board includes optical relays and decoders for I/O control of the device under test, as well as on-board voltage and current monitors

-

The Python script monitors voltage and current levels as the load demand of the power regulator increases

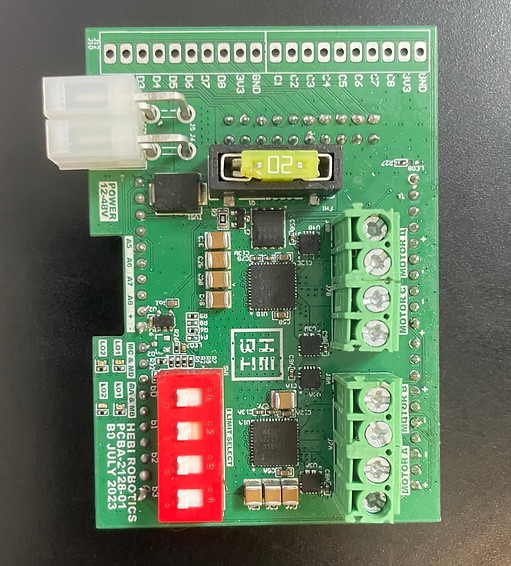

Motor and LED Driver

-

First, I prototyped just the motor driver since the LED driving circuit had already been validated

- Motor Driver Specifications:

-

Drive 4 brushed DC motors (for air pumps) at up to 5A with bidirectional phase current sensing and limiting

-

-

Testing Results:

-

Current sensing was not high enough resolution

-

Motor speed did not have enough range

-

-

Conclusions for next iteration:

-

Select current sensor with smaller range, higher resolution

-

Select motor driver with higher frequency control

-

Version 2:

-

Version 2 includes 2 LED boost buck driver circuits, 2 motor drivers, one switched 5V/5A output, onboard connectors for ethernet switch and MCU module, and four SPI channels

bottom of page